Mantenance 5.0

DESDEMONA Project

smart maintenace

State of art

Although Industry 4.0 laid the foundation for the digitization of industry, it is with Industry 5.0 that workers’ welfare will be placed at the center of production processes. The hallmark of this revolution is a focus on social value that attempts to drive action on sustainability and promotes talent, diversity and empowerment rather than focusing primarily on profits and economic growth. Industry 5.0 profoundly restructures human activities by shifting labor from manual to cognitive to provide value-added activities in manufacturing. Worker cognitive skills will be increasingly important in industrial environments. The transition from the computer-centered era of Industry 4.0 to the new human-centered era of Industry 5.0 has led to disruptive changes resulting in the concept of “smart maintenance.” Maintenance activities represent one of the largest investments required for today’s industrial transformation, where most companies are experiencing significant worker hesitation in adopting new technologies. The complexity of a maintenance activity may depend on various aspects, such as working on an ongoing process, time pressure, and machinery with different components, requiring an understanding of methods and processes unique to each activity. The effects due to an inefficient maintenance policy can be very impactful for a company. They can be summarized as reduced safety, high unplanned downtime, process inefficiency, reduced asset life, and increased costs. Augmented Reality (AR) and Artificial Intelligence (AI) can be the real game changer in maintenance activities. These enable:

• Visual Assistance

• Training and Education

• Remote Support

• Reduction of Errors

• Increased Efficiency

• Improved Diagnosis

• Safety

• Time and Cost Savings

• Personalization

• Interactivity and Involvement

Industry 5.0 will significantly increase the efficiency of production, maintenance, monitoring and supervision and create adaptability between man and machine, approving responsibility for interaction actions. However, while the introduction of more complex technologies (e.g., AR, AI, etc.) brings substantial benefits in terms of productivity and performance, the adoption of the smart devices require great efforts in terms of skills, generating usability problems as a direct consequence, especially by SMEs. Therefore, when the maintenance procedure, while supported by most smart devices, fails to avoid or minimize the consequences of an accident, the pertinent question is, “Is the procedure wrong” or “Did the person get it wrong?”

fast foward thinking

Our approach

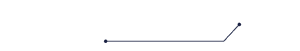

The idea is to develop a decision support system (DSS) to provide real-time suggestions on appropriate operators to perform maintenance tasks with high cognitive workloads. Given the complexity of the maintenance task to be entrusted, the DSS suggests the most suitable operator by considering the available workforce based on three main factors: operator profile (i.e., skills, hard skills, age, etc. ), emotional state of the operator, and available smart devices.

The objective pursued by the project can be achieved according to three main steps. The first step is to develop an analytical model to assess the cognitive workload of common maintenance tasks. The analytical model evaluates, on the one hand, the cognitive content maintenance tasks (independent of human performance) and, on the other hand, the profile of the operator to whom the task might be assigned. The second step is to explore the problem of real-time detection of a worker’s emotional state and performance during the performance of a maintenance task to see whether the assignment of a given task to a worker generated a stable or unstable response (e.g., is the worker calm, relaxed, and confident? How does the worker’s emotional state vary from the assignment, throughout the performance?). This response is useful to implement a human-in-the-loop approach in a DSS and create an algorithm based on reinforcement learning that improves the assignment decision based on real-time responses. The last step is devoted to identifying the most suitable device to support the operator in maintenance activities. A virtual environment is developed in which operators can receive real-time instructions on key maintenance tasks, thus making maintenance activities more efficient, flexible and safe. Thanks to the use of specially chosen programming languages, all the virtual elements useful for the realization of simulation, training and maintenance support sessions are introduced within the application.

desdemona project

Vision

” As Desdemona in Othello redefines women’s role in society by overcoming the restrictions and the systems’ strength, our “DESDEMONA” will redefine the operators’ roles in the maintenance task, aiming to increase industrial flexibility, and ensure human well-being “

what and how

Goal & Methodology

DESDEMONA proposes the development of an innovative analytical model to estimate the cognitive demand of maintenance tasks, based on the principles of information theory, and evaluate the cognitive workload considering both individual human processing rate and environmental aspects. The methodology used will involve the use of object-oriented programming (in the Mixed Reality Toolkit environment) for cross-platform mixed reality. The set of components and functionalities of this programming paradigm enables accelerated development of cross-platform mixed reality applications via building blocks for spatial interactions and user interface, while ensuring the development of custom prototype applications via the Unity graphics application and C++ programming language. The model is based on the integration of multimodal approaches, combining facial recognition and other bio-signals for more reliable prediction of operators’ emotional state. In addition, the project aims to redefine the role of operators in the maintenance context, increasing industrial flexibility and ensuring human well-being, using advanced technologies such as augmented reality (AR) and mixed reality (MR).

Contact

- Email: desdemonaproject2024@gmail.com